Qtagg

Redundant network helps improving efficiency and lower CO2 emissions for marine vessels

The demand for more environmentally friendly solutions is growing within the marine industry. Many operators set ambitious targets and seek- out suppliers that can reduce the environmental impact and greenhouse gas emissions of their business. Qtagg is a leading Swedish provider of intelligent propulsion control systems with focus on fuel efficient and sustainable solutions for the shipping industry. The company’s products and systems are used by some of the world’s leading shipping companies and are installed on all types of vessels, including ferries, container ships, cruise ships, chemical tankers and very large crude carriers.

“We believe there is a huge opportunity to improve the efficiency within the shipping industry using this approach. Instead of building new ships, we add smart software to leverage the existing investments.” says Tomas Lindqvist, CEO of Qtagg.

Minimising downtime to install and maintain onboard equipment is critical to operator profitability. A key advantage of the Qtagg control systems is the ability to install them while the ship is in normal operation. However, this requires that the complete system, including supporting data communications network, to be very simple and efficient to install. The environment on board ships where the Qtagg systems are installed is exceptionally challenging for the supporting data network. There is constant heavy vibration, dirt, oil residue and heat, all of which places a major strain on the equipment. The Qtagg products are specifically designed to operate in these tough environments, but to ensure the complete solution operates reliably, it is essential that data communications network offers similar exceptional levels of robustness and reliability.

Qtagg propulsion control system monitors in ship command bridge.

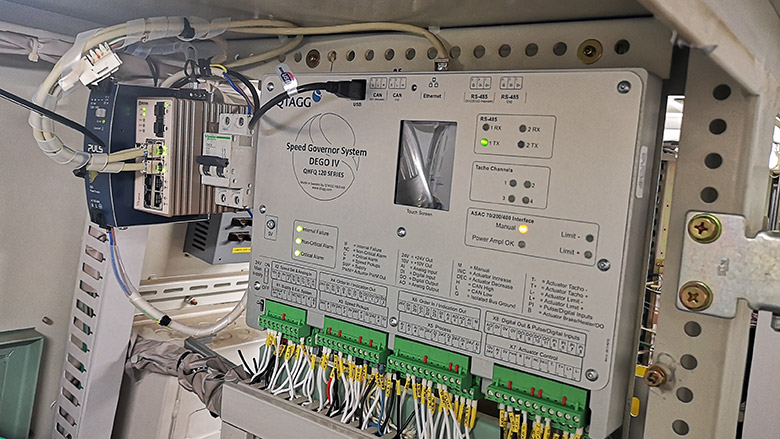

Westermo’s Lynx switch installed next to Qtagg’s DEGO speed governor system.

Customer requirements

Qtagg provides a fully integrated system that automatically controls the ship to arrive on time at the lowest every voyage. To enable this solution, the different components must communicate with each other with high speed and without interruption. Qtagg turned to Westermo for the necessary support.

“With both companies being located in Västerås this made it easy for us to collaborate and gain from each other’s expertise,” said Tomas Lindqvist, CEO of Qtagg, about choosing Westermo as their supplier.

When identifying the right data network technology provider, the most important factor was the availability of devices with DNV GL marine type-approval, which ensures the technology can withstand the extreme temperatures, humidity, extreme vibration, shock and EMC noise typically found on board vessels. EMC immunity, the availability of fibre optic ports and passive cooling that helps to contribute to greater reliability and lifespan were also important factors. Westermo’s Lynx L110-F2G Ethernet switches were selected to create and manage the data network. With DNV certification, a mean time between failure (MTBF) of 630,000 hours, robust casing and EMC resistance, the switch provides the ideal solution. Additionally, the small footprint and compact design allowed the Lynx to be installed in the confined spaces typically available where the Qtagg equipment is installed.

“Our customers have very high demands relating to system availability. The systems also operate in a very challenging environment, which is why we chose Westermo as our supplier of industrial data communication technology. Westermo share the same values that we do, and therefore it has been a perfect match,”

explained Lindqvist.

Redundant solution

In addition to the robustness of the hardware, Qtagg also needs a solution that creates a redundant network. Should a network failure occur, it is critical that the system continues to function without interruption, since the ship could be out at sea. By adding redundancy, this provides greater network resiliency ensuring systems remain operational until failed components can be repaired or replaced when the vessel reach the next port.

Working with Westermo, Qtagg designed the data network using WeConfig, Westermo’s network configuration tool, which makes configuration and maintenance more efficient, simple and reliable. Westermo’s own robust and reliable FRNT (fast recovery of network topology) protocol was used to build resilient ring networks that offered a high level of redundancy. In the event of network link failure, the FRNT protocol quickly reroutes the data around the ring network ensuring the network remains functional and no data is lost.

Westermo’s Lynx switch installed on Qtagg’s test rig.

“A reliable and effective communication solution is necessary for our systems to work properly. Westermo’s networking technology meets both our own, as well as our customers’ high expectations and demands in terms of quality and performance,” commented Lindqvist about the partnership.

“Westermo’s solutions are primarily about solving data communications problems for customers and our mission is to provide the digital infrastructure that a customer needs to be able to focus on their core mission,” explained Henrik Jerregård, Product Manager at Westermo.“ In this case, Qtagg has applied a network solution that allows their propulsion systems to operate concurrently to ensure that fuels costs and emissions are minimised.

See also

DNV GL marine approved products

See our range of DNV GL approved products for marine and offshore applications.

Robust network solutions for the marine industry

Westermo offer a comprehensive range of secure ship-wide Ethernet solutions, approved for maritime use.

Carl de Bruin

International sales

Jos tarvitset asiakastukea, ole hyvä ja käytä tukilomaketta