Quality proven over decades

When you see Westermo products still operating in installations after two decades, it’s not luck. It’s the result of relentless commitment to quality. From Solder Paste Inspection and Automated Optical Inspection to X-ray examination, every stage of manufacturing is backed by rigorous testing. Add PCB validation and burn-in testing, and you have equipment engineered for a long operational life, even in the harshest environments on the planet. That’s why rail operators worldwide trust Westermo for reliability that lasts.

State-of-the-art manufacturing in Europe

- ISO9001 and IPC-A-610 certified

- Industrial grade components

- Prototypes produced in-house

- State-of-the-art electronic manufacturing testing

- External testing by third party test laboratories

Best in class software validation

- Continuous and automated software testing

- 15 test servers in continuous operation

- 30 000 test performed in a week on over 50 product variants

- Westermo offers the most reliable and most widely tested software on the market

Industry Approvals

- Tested and certified through independent and well-known test laboratories

- Shock and vibration, EMC, IP 65 tests, Safety tests, UL, EX, DNV

- Extensive in-house hardware validation and testing

- Dry heat/Cold start, Power tests, HW verification, Isolation tests, Ethernet compliance

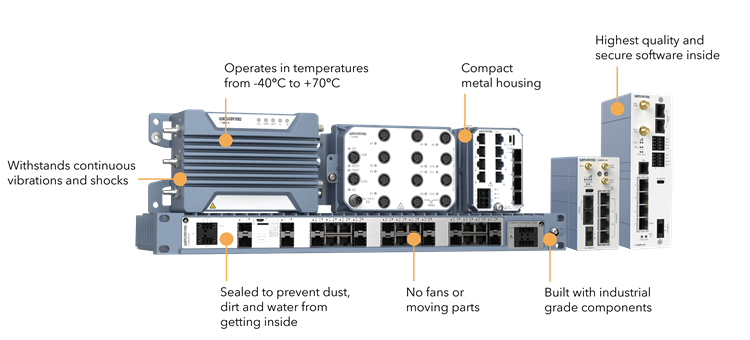

Ultra-robust industrial grade hardware

Applications and use cases for rail

Westermo provides products and solutions for most networking applications within the rail industry. Our extensive product range and deep understanding of rail applications ensures that we can offer the best solution for your needs.

Multigigabit train-to-ground connectivity

Using MMWave technology, Westermo provides high-speed train-to-ground connectivity solutions.

Digital Interlocking

Networking solutions from Westermo combine traditional safety-oriented railway systems with modern network security solutions.

Communication Based Train Control

Westermo can offer the network products required for a complete CBTC solution.

Train Control and Management Systems

Westermo can support critical subsystems inside trains with robust and secure data communication systems.

Digital Payment Systems

Westermo offers a variety of network solutions for connecting digital payment systems that are typically found on board trains and at train stations.

Rail Electrification

Westermo’s rail offering addresses all the needs of the rail electrification value chain.

Predictive Maintenance

Westermo offers products developed for connecting rail assets and accessing reliable data.

Onboard Connectivity

The Wi-Fi solutions available from Westermo resolve issues caused by high-density applications.

Rail Asset Management

Westermo can provide many types of data communication solutions to connect rail assets over different types of media.

Public Address and PIDS

Westermo offers products and expertise in creating reliable and robust network solutions for all types of public address and information display systems.

Video Surveillance

Westermo has developed data communication products specifically for solving common challenges within CCTV and video surveillance systems in public transit.

Khawar Naeem

Sales, Trains and Trackside

For support inquiries, click here to contact Technical Support